Your BIM-VDC Professionals

About Us

ProtoCAD Designs, Inc., an Oregon Minority Owned business, has been in business since 1998, providing high quality on and off-site BIM, engineering, design, detailing, spooling and CAD services. We provide a wide range of Engineering & Design services including: Plumbing, Mechanical and Process Pipe for market sectors that include Commercial, Industrial, Healthcare, Manufacturing, Bio-Med, High-Tech and Multi-Residential. We have excellent working relationships with regional contractors, engineers, direct clients and vendors.

At ProtoCAD Designs we provide a team that works directly with our customers; from Design/Development, Engineering, 3D Facility Scanning, BIM, Construction and Fabrication Documents all the way through Services during construction. ONE team, ONE vision, ONE goal: to provide the highest quality product for our customers.

With over 80 years of combined experience in Building Information Modeling (BIM), we can provide designs in 2D or 3D. With our skill sets, we are able to quickly identify interferences, assist with coordination issues and streamline the generation of material take-offs, spools and fabrication drawings. Simply put, our expertise enables our clients to save time, minimize costs, and achieve success.

Our Specialties

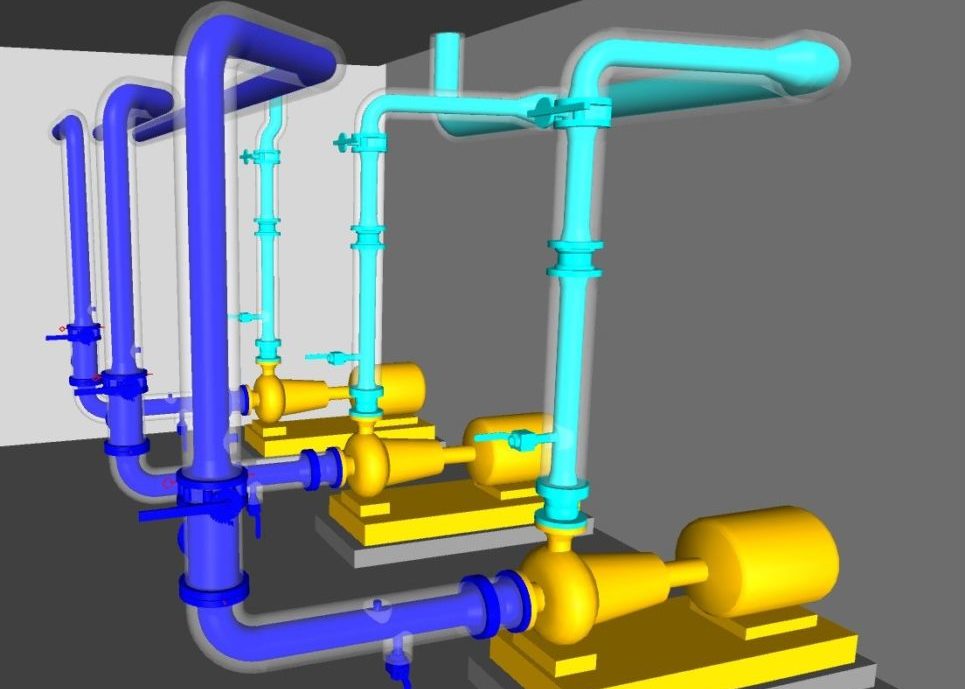

Mechanical Piping

Process Piping

Plumbing

AutoCAD Plant3D

Autodesk Revit

Navisworks Manage

Our Workflow

Design and Engineering

ProtoCAD works directly with Owners and Contractors to provide Engineering and Design for the Mechanical/Process/Plumbing market sectors. When the base design is done, the ProtoCAD team smoothly transitions to full BIM and Construction Documents to provide continuity from Base Design through Services During Construction.

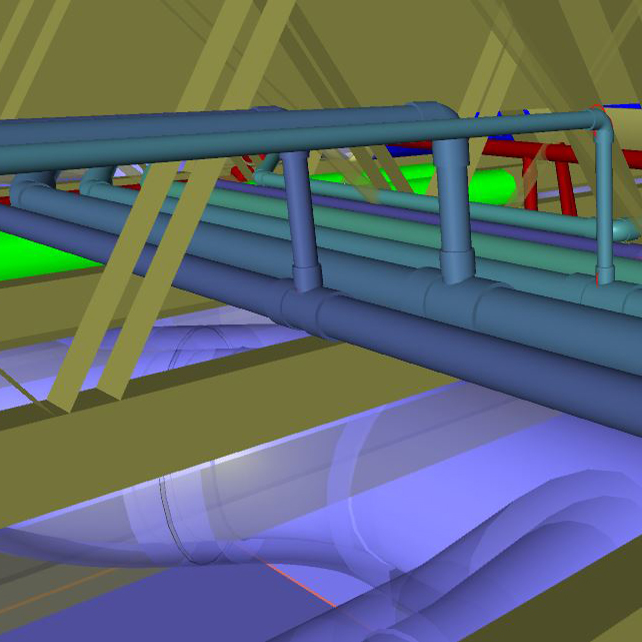

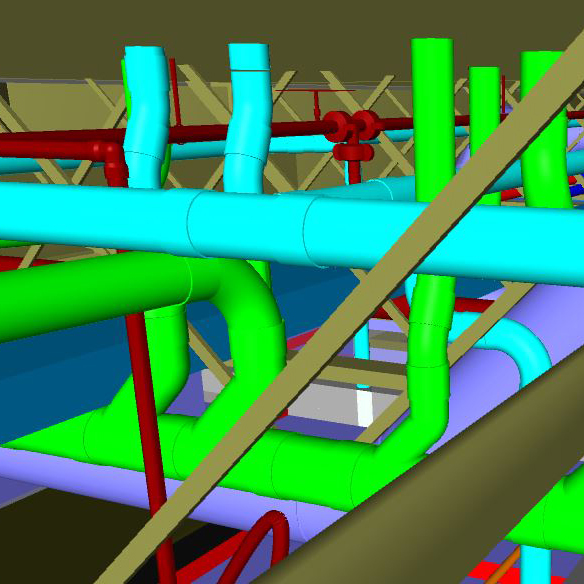

Modeling and Coordinating

We start by compiling all the engineering documents: specs, P&IDs, design models, meeting notes, RFI's and incorporating them all into the 3D building model. We then coordinate the model spatially in cooperation with all the other trades on the project. Here we can identify constructability issues such as access, ergonomics, and clashes before they become real world problems in the field. We also identify areas where we can minimize welds and fittings in order to save time and resources.

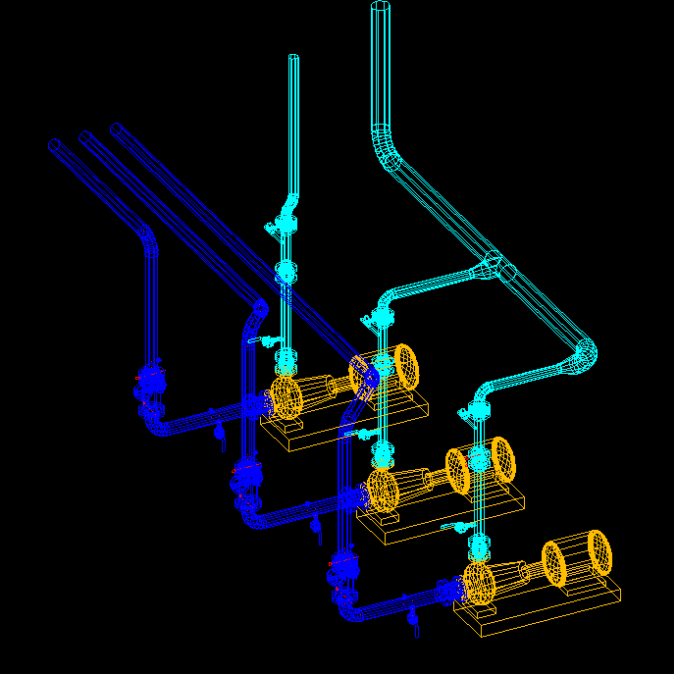

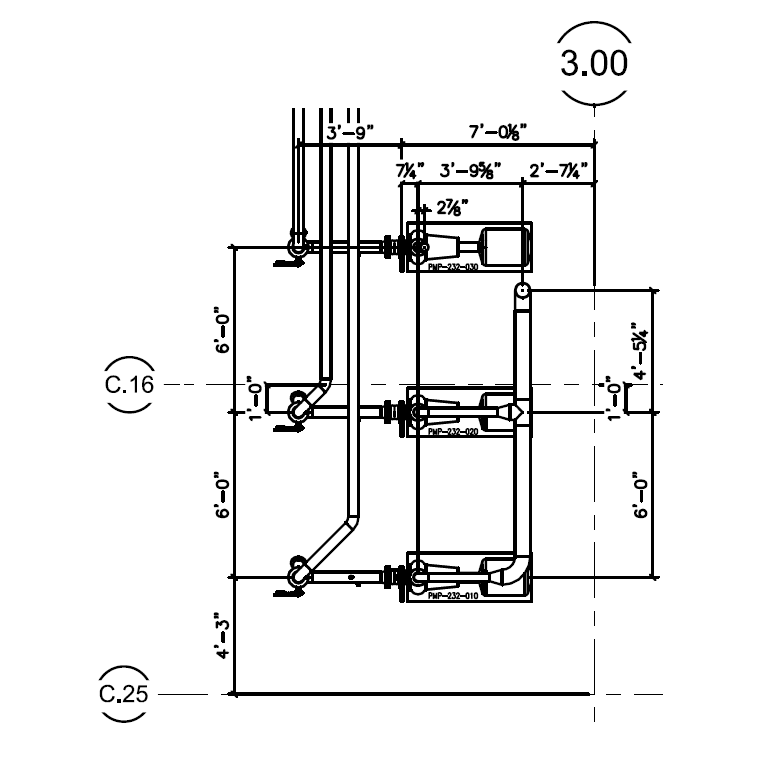

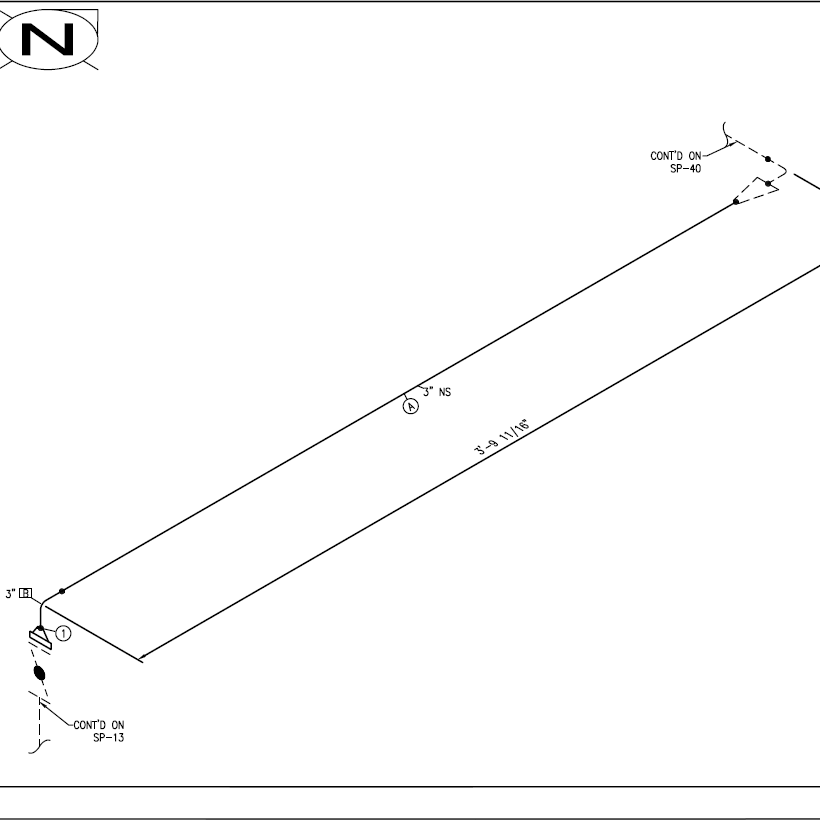

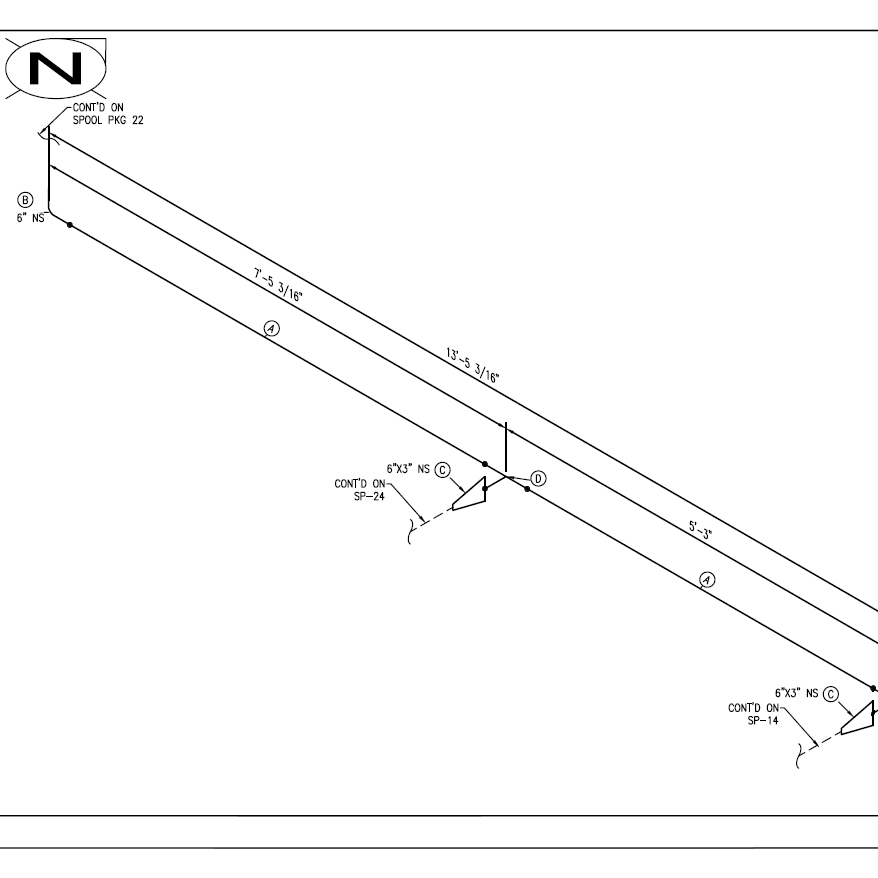

Shop Drawings & Spool Maps

Once in the model, we dimension out our systems against known grid lines and monuments in order to easily locate and maximize efficiency in the field. Additionally, we provide isometric views and map out all spool pieces in the model.

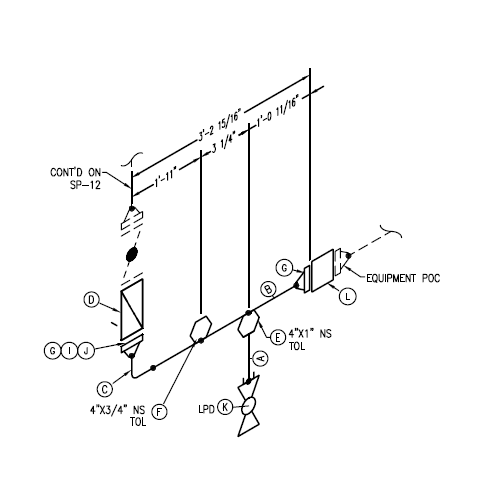

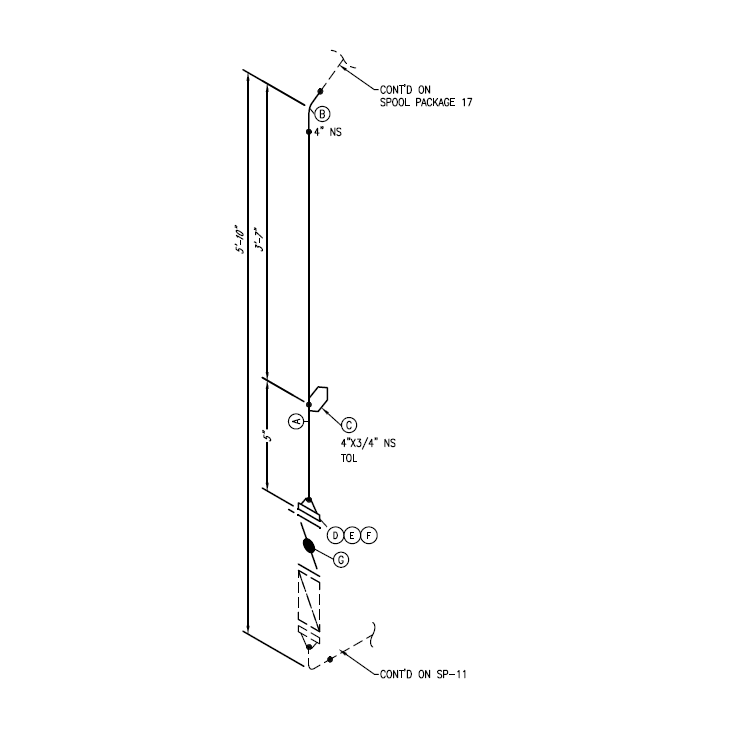

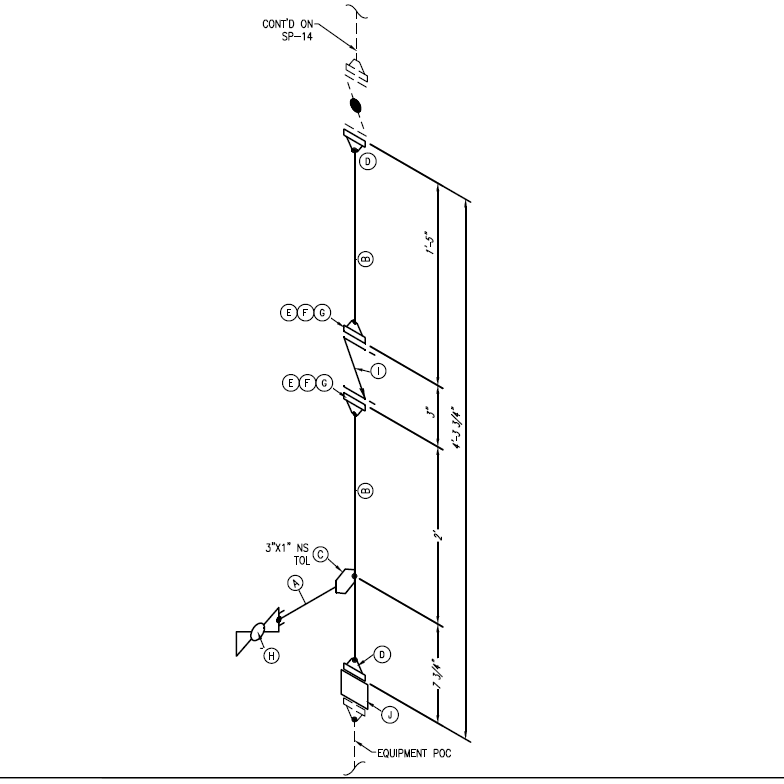

Spooling and Fabrication

Once modeled, dimensioned, and QA/QC'ed against the engineering documents, we start releasing spool packages. These packages, complete with a BOM on every spool sheet, will allow you to pre-fabricate the majority of the spool pieces off-site. Once fabricated, the spool pieces can be transported to the field and installed.